Design Criteria

We were approached to design and build two prototype plants capable of producing 500 l/h of permeate from saline water, capable operating worldwide. The main requirement is that they had to be capable of being carried by four people, with a weight limit in the region of 100 kg (based on 25 kg x 4 people) as well as undergoing climatic trials due to the varying environments in which they are intended to be used.

Design Solution

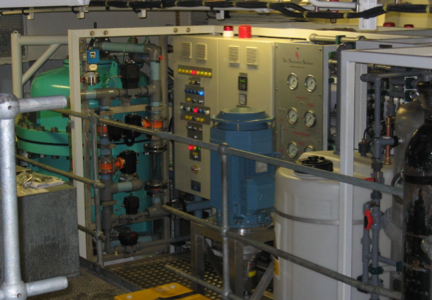

To ensure that we could meet the weight specifications, a modular design had to be utilised. The plant was manufactured in two halves consisting of an electrical control module and a RO module which are connected using flexible hoses.

A number of components used were new to Salt Separation Services due to the constraints of the design criteria – significant measures were taken to reduce the weight. Custom designed valve manifolds were selected over traditional valves, these occupied a smaller space envelope and reduced the number of components/fittings required.

Initially a GRP control panel enclosure was used to house the electrical components, however, after issues during EMC testing these were retrofitted with stainless steel enclosures, this resulted in an increase in weight due to the change of material.

The vessel module was originally designed to house four RO vessels, during the testing phase the module was deemed to be too heavy once membranes were fitted, the design was adapted to reduce to three vessels utilising an alternative membrane to give the same flow and product water quality and a weight reduction of 17 kg overall.

To further reduce the weight, aluminium was used for the framework, which is lightweight when compared to traditional steels.

On completion of prototype testing, a contract was awarded to manufacture a number of RO plants for operational requirements.