We have recently become the first UK and Northern Ireland licensee for DuPont™ DesaliTecTM’s Closed-Circuit Reverse Osmosis technology, further expanding our capabilities to deliver high quality water treatment solutions.

With DuPont™ CCRO, it is possible to achieve recovery rates as high as 98% with the typical being 90 to 95%. This gives clear advantages over traditional RO including:

- Up to 90% less water waste

Through maximising the recovery of the water from waste, the volume of waste discharged will subsequently be reduced.

- Lower energy consumption

Comparing with a normal RO plant with same amount of recovery, DuPont™ CCRO will achieve better specific energy (kWh/m3).

- Reduced CIP requirement and frequency

DuPont™ CCRO will require much less CIP (e.g., every 6 months) compared to conventional RO (e.g., monthly). Additionally, as there is only one stage with CCRO, all RO membranes are cleaned at once, enabling a quicker cleaning procedure.

- Feed flexibility

Autonomous nature of DuPont™ CCRO enables handling of a variable feed.

- Scaling and fouling resistances

Advantages against silica, sulphate and phosphate fouling and able to take on higher TOC, BOD and/or COD in feed than traditional RO.

- Compactness

Smaller plant size with DuPont™ CCRO, compared to a normal RO achieving same water recovery.

CCRO Technical

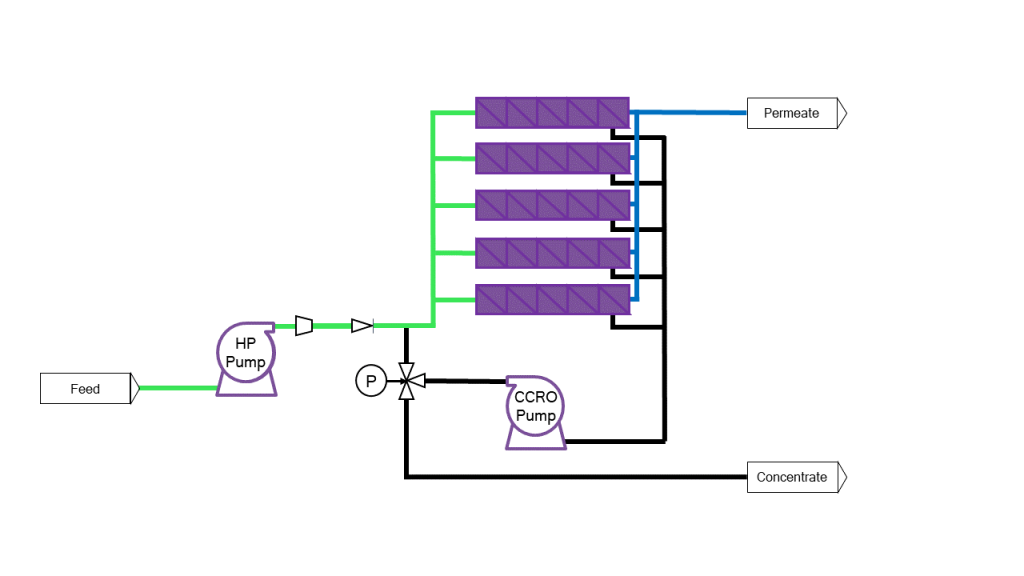

The technology can be summarised as recirculating the brine back into the RO feed until an operational trigger signals for plug flow instead of the closed-circuit mode. While this makes the brine more concentrated with each pass, it enables recovery of water from the waste.

As the concentrate is recirculated into the feed, this increases the osmotic pressure of the feed and eventually triggers the discharge mode, i.e., opening the purging valve. Permeate production is not interrupted during plug flow. Once the osmotic pressure normalises the system returns to closed-circuit mode.

While the osmotic pressure is the main trigger, there are 4 parameters in total that can control the system to switch modes, they are:

- Osmotic pressure of feed;

- Conductivity of feed, concentrate and permeate;

- Permeate quality;

- Recovery rate.

In the coming months we will be commissioning a pilot plant. This plant will be available for conducting pilot plants on customer sites to demonstrate and validate the process for possible future installations.

All plants delivered will come with a minimum recovery rate guarantee contingent for the first 6 months from date of satisfactory performance tests.

For further information contact our sales team.

Email: terri.thompson@saltsep.co.uk, jiehong.shen@saltsep.co.uk or at sss@saltsep.co.uk.

Phone: +44 (0) 1706 655 522