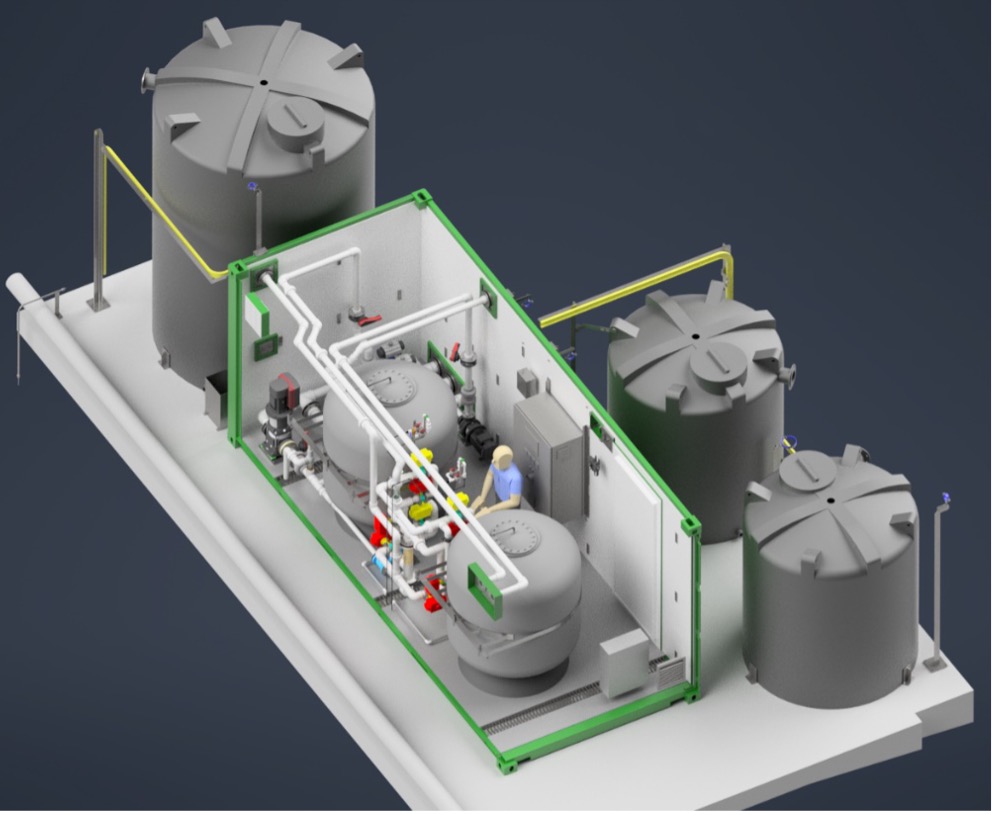

20ft Containerised 29 m3/h Iron and Manganese Filter system

Other than our core specialisation in Reverse Osmosis (RO) we also offer expertise in a variety of water treatment technologies, including Nanofiltration, Ultrafiltration, Microfiltration, Ion-Exchange, post-treatment and pre-treatment packages.

In May 2023, we successfully designed, manufactured, installed and commissioned a bespoke water treatment system for a UK-based food production site to replace a borehole water treatment system which showed significant signs of aging.

The Challenge

The existing system consisted of three media filters in a duty/duty/standby configuration. These filters were stationed outside by the borehole water source without proper weather protection and fitted with simple ABS pipework.

The system was critical to operations, as it supplied cooling water across the factory and reduced the usage of the mains water supply. However, after more than 30 years of service, the system exhibited significant issues such as, brittle pipework, frequent component failures and rapid filter blockage rates to name a few. These challenges highlighted the urgent need for a modern, reliable solution to ensure continued operational efficiency.

Our Solution

To replace the old system, we delivered a custom-built 20-foot containerised filter package, capable of treating up to 29 m3/h of borehole water. The package included chlorination and three large external storage tanks.

The new system provided filtered water, removing relatively large, suspended solids that may be present in the raw water in addition to the removal of iron and manganese. A filtration velocity of 9 to 10 m/h was specifically chosen for the sizing of the filter vessels to ensure effective removal of iron and manganese while preventing clogging of the existing heat exchanger equipment downstream.

Equipment Overview

The fully self-contained, pre-piped and pre-wired package included the following major components:

- 20’ ISO high cube container with modifications such as lighting, heating and ventilation.

- Feed pump.

- Forwarding pump.

- Backwash pump with variable frequency drive (VFD).

- Two 1400mm media vessels.

- Dosing pump with necessary ancillaries.

- Container-bound and external piping & wiring.

- Instrumentations.

- Localised control panel.

- Three External storage tanks.

System Design Features

The media vessels were partially filled with a calculated ratio of:

- 3-6mm gravel

- 2-3mm gravel

- 16/30 sand

- Manganese dioxide

This combination provides effective filtration while leaving a void above the media to allow for bed expansion during filter washing.

Manganese dioxide removes both iron and manganese from water by catalytic oxidation. During the reaction the manganese dioxide media is reduced (exhausted) and its oxidative action ceases, before this happens the manganese dioxide requires re-oxidising (regenerating), to achieve this, sodium hypochlorite is dosed into the raw water.

Outcome

The bespoke filtration system now delivers reliable performance, meeting the site’s operational needs and ensuring a consistent supply of treated water. This custom solution has improved water quality, reduced equipment downtime and improved the site’s overall efficiency. For more information about our custom water treatment solutions, contact us at sss@saltsep.co.uk today.