Design Criteria

A water treatment plant was needed to facilitate an increase in drinking water production on an offshore platform. The requirement was driven by additional staff on board to decommissioning the oil rig. The brief asked for a downsized plant which could be easily unloaded, installed and set to work with minimal design or technical input required. The plant had to be fully compliant with ATEX so that it can operate in a hazardous area (Zone 2), with little operator training and minimal chemical usage requirement.

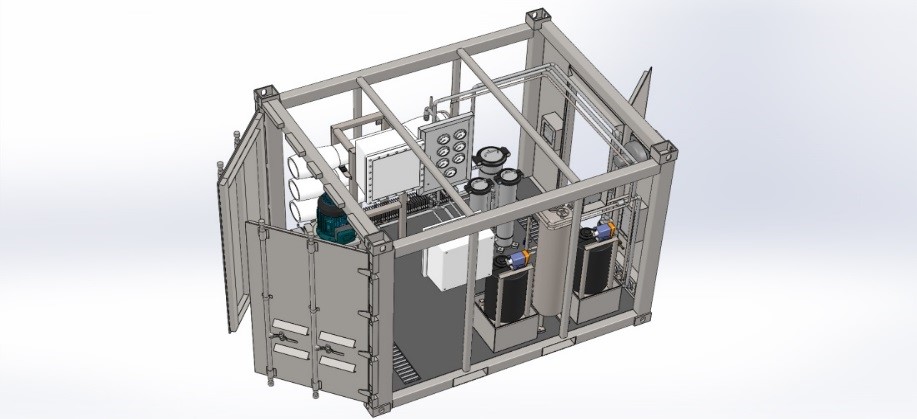

Design Solution

To keep the size down, multistage bag filtration and over-sized cartridge filtration was utilised. Commercial off the shelf units were not available, so Salt Separation Services designed and manufactured our own.

A chemical injection system was introduced to remove chlorine rather than fit a heavy carbon filter. Although this meant chemical addition (which we were trying to avoid), the benefits on footprint and weight were far too significant.

After the design phase a unit was manufactured with the intention that it would be available for hire to offshore installations enabling evaluation in its intended market. However, the first customer to hire it decided that they wanted to purchase the unit.

We have since manufactured an identical unit which is available for hire.